Details of A-Type Automatic Layer Cage Farm with 30,720 in Zambia

This fully automated chicken farm project in Lusaka, Zambia is very important. Zambia has an advantageous geographical location, huge market potential, convenient transportation, and many ports to choose from for imports. The government has provided support to the breeding industry and granted a series of preferential policies such as rapid loan approval. In order to realize the modernization and rapid development of the farm, Mr. Alikhadio ordered a set of fully automatic A-type layer chicken cage system from us, including automatic feeding equipment, automatic egg collection system, automatic manure cleaning equipment, feeding tank, fan and wet curtain system. The introduction of fully automatic chicken cage equipment reduces the use of workers. At the same time, reasonable planning of chicken houses also helps to reduce the spread of diseases, which is beneficial to the management of farm employees and the healthy operation of the farm. The entire project will take about 6 months of construction time. During this time, we will assist the customer to complete production, transportation, customs clearance, etc., and finally complete the installation and commissioning of the equipment.

What are the chicken farm design and solutions of a fully automated farm with 30,000 chickens?

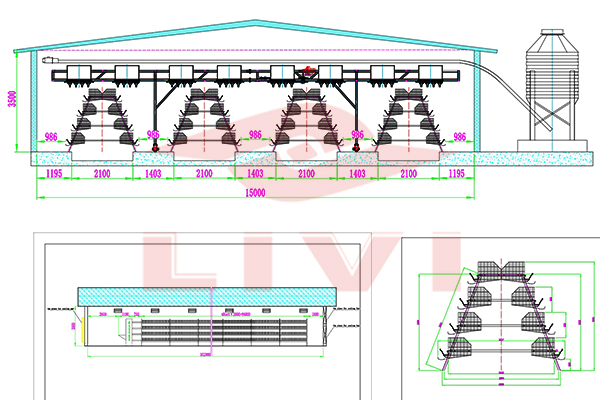

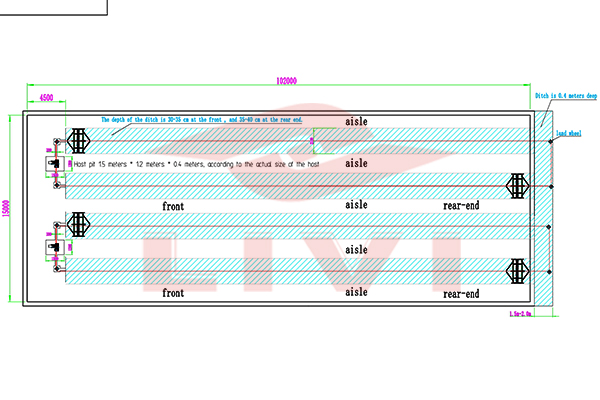

The design drawings and plans of this fully automated chicken farm take into account the dimensions of the chicken house and the layout of the automated A-type layer chicken cages. The dimensions of the chicken house are 102 meters long, 15 meters wide and 3.5 meters high, providing ample space for the chickens to move around. The layout of the chicken cages adopts 4 rows, each row has 48 sets of hot-dip galvanized laying hen cages, which can raise a total of 30,720 birds. This design maximizes the utilization of the chicken house and facilitates breeding management.

Why Mr. Alikhadio choose A-type automatic layer cage system?

The application of the Type A automatic layer cage system in Zambia’s 30,000 chicken fully automatic farm has brought many advantages and benefits. First of all, this system can provide an efficient breeding environment. The design and layout of the chicken house allow the chickens to obtain enough space and comfort, which is conducive to their growth and egg production. Secondly, the automation function of the system reduces the need for manual operation, saves labor costs and improves work efficiency. The automatic feeding equipment ensures the feed supply for the chickens, and can carry out intelligent control according to the needs to keep the feed fresh and reasonable. The automatic manure cleaning equipment treats the manure in a harmless manner, effectively reducing environmental pollution and smell problems, and improving the sanitation of the farm. The automatic egg collection system can collect eggs promptly and accurately, improving egg quality and yield.

In addition, the A-type automated laying hen cage system also has advantages in energy utilization. The fan and wet curtain system can provide good ventilation and cooling effects, provide a comfortable environment for the chicken house, regulate the body temperature and humidity of the chickens, and are conducive to the healthy growth of the chickens. The system’s intelligent control capabilities can also be adjusted according to the season and the needs of the chickens to achieve energy saving and optimal utilization of resources.

What we can serve for our customer?

1. High-quality poultry farming equipment: chicken cages for layers, broilers, pullets.

2. Free chicken farm solutions

3. Free Chicken house deisgn

4. A-Z chicken farm services

Copyright © 2022 Zhengzhou Livi Machinery Manufacturing CO.,LTD. Power by SinoArt