Type: A-Type

Tiers: 3-4 Tiers

Applicable Industries: Poultry Farms

Use: Baby Chicks

Specification: 1950mm*500mm*350mm.

Raw Material: International Q235 bridge-steel.

Anti-corrosion Treatment Process: Aluminum-zinc alloy, Hot-dip galvanized.

Life Time: 15-20 Years

Certification: ISO 9001,SONCAP,CE.

Send us email

info@livichickencage.comCall us/WhatsApp

+86 173 1975 0880● Dung board: there are dung boards under each floor of cages to avoid dung leak.

● Suitable for different days old chicken to drink: automatic drinking system like hanging cups and water pipe lifting system, both of which can meet the chicken's drinking needs in different growth phases.

● Water tank with calibration or pressure regulator, it is easier to control water consumption.

● Plastic bottom net: it's laid flat on the bottom chicken cage mesh to avoid baby chick drop down in the first ten days.

Automaitc Pullet Battery Chicken Cage Farm Specification

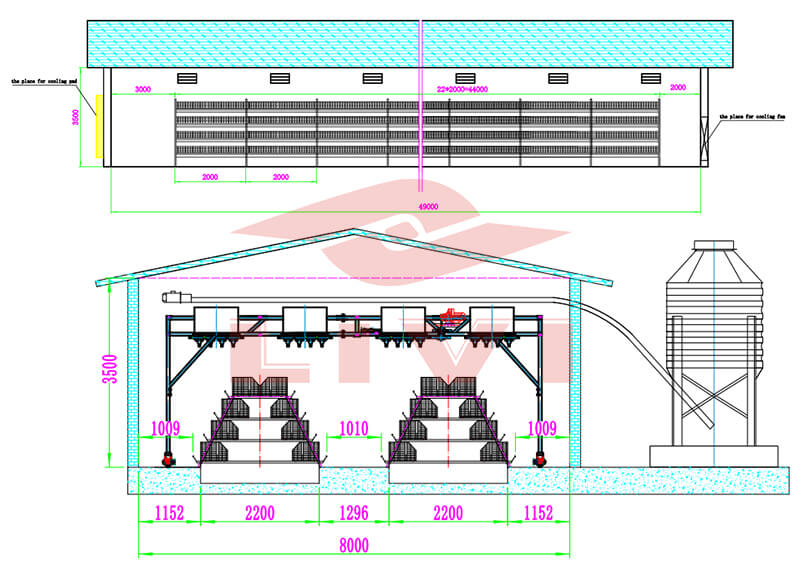

A-type manual pullet cage system usually used for 5,000-20,000 birds chicken farms. For 10,080 pullets, if 3-tier cages are installed, 28 sets of cages per row, 2 rows in one house. Totally 10,080 birds pullet can be raised. For 15,000 pullets, if 3-tier cages are installed, 28 sets of cages per row, 3 rows in one house. Totally 15,120 birds pullets can be raised. We can provide free chicken house design according to our customers' requirements.

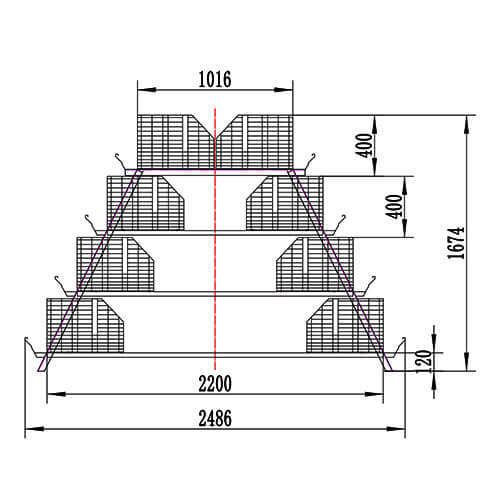

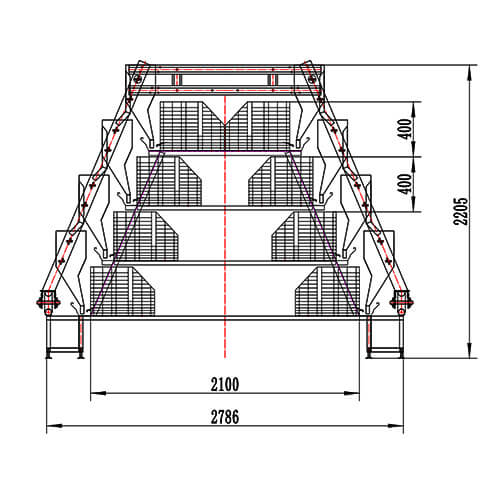

A-Type 4-Tier Pullet Cage Specification

A-Type 4-Tier Automatic Pullet Cage Specification

The normal size of the manual pullet cage system is 1950mm*500mm*350mm , but support customization. Contact us now for more details!

|

Automaitc Pullet Chicken Cage Specifications |

||||

|

Type |

Door/Tier |

Birds Qty/Door |

Birds Qty/Set |

Specification |

|

A-type |

3-tiers 3-door |

10 |

180 |

1950mm*500mm*350mm |

|

4-tiers 3-door |

10 |

240 |

1950mm*500mm*350mm |

|

● The manual system for baby chicken cage is composed of 7 parts: cage mesh, cage bracket, water nipple, water pipe, water pressure valve, feed trough, and small accessories. It is basically used for quantity below 15,000pcs bird poultry farm project.

● Semi-auto system for layer chicken cage is composed of a manual system, and a feeding trolly or gantry feeding system, or a ladder feeding system for feeding part, an optional scrapper manure removal system. It can reduce human labor greatly with less electric cost.

● Auto drinking system is composed of water pipe, water nipple, water nipple cup, and water pressure valve, it can make sure the pressure is equally same from the front side to backside.

Manual Pullet Cage System

Automatic Pullet Cage System

Automatic Drinking System

● Auto feeding system: Auto feeding system has three options, gantry feeding system, ladder feeding system, and feeding trolly.

● Auto manure removal system: auto manure removal system has two options, scrapper manure removal or belt manure removal system, they can make sure you have a clean shed, less mortality with less ammonia.

● Auto ventilation system: Auto ventilation system can keep the shed in a certain range of temperature, in the meantime, the auto control system can reduce the electric consumption for the ventilation system.

Automatic Feeding System

Automatic Manure Removal System

Automatic Venlitation System

Copyright © 2022 Zhengzhou Livi Machinery Manufacturing CO.,LTD. Power by SinoArt