In modern poultry farming, efficiency, productivity, and hygiene are crucial factors for large-scale operations. With the growing demand for eggs worldwide, farmers are increasingly adopting automated solutions, particularly H-type layer battery cage systems, which offer a comprehensive approach to raising layers efficiently while minimizing labor costs.

The H-type layer battery cage system is designed to optimize space utilization, ensure proper ventilation, and facilitate management of large flocks. Unlike traditional A-type cages, H-type cages allow for multi-tiered layouts, making it possible to house tens of thousands of chickens in a single farm while maintaining a controlled environment.

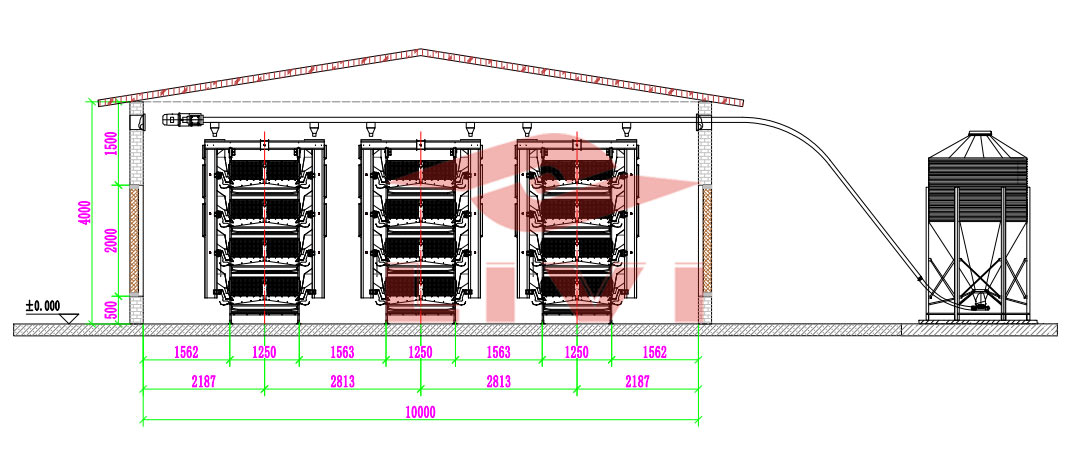

Efficient farm layout is essential to maximize productivity. When using H-type cages for large-scale farms, consider the following factors:

Calculate the number of h type chicken cages based on the total flock size. For example, a 30,000-layer farm with cages housing 144 birds each can achieve optimal density using multi-tier H-type cages arranged in thress rows.

Proper air circulation prevents heat stress and respiratory diseases. Combining automated systems with natural or artificial lighting ensures hens remain productive year-round.

At a 20,000-layer farm in Aruba, H-type cages were installed across multiple chicken houses:

Results:

In Colombia, a large-scale poultry farm with 60,000 layers implemented the H-type layer battery cage system to maximize productivity and maintain high hygiene standards. The farm setup included:

Results achieved after implementation:

For modern poultry farmers seeking efficiency, scalability, and hygiene, adopting an H-type layer battery cage system with automation is a smart investment. Proper layout, ventilation, and equipment placement ensure high productivity while minimizing labor costs and disease risks.

Whether planning a 10,000-layer or 50,000-layer farm, this system provides a flexible and efficient solution to meet growing market demands.

Copyright © 2022 Zhengzhou Livi Machinery Manufacturing CO.,LTD. Power by SinoArt